Earlier this week, researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) presented a new MultiFab printer at the annual computer graphics conference SIGGRAPH. For all of the promise that 3D printing seems to offer, additive manufacturing techniques tend to have been limited to one material at a time. That is, until now. The new MultiFab printer, which is still under development, can work with up to 10 materials simultaneously. Needless to say, this has huge implications.

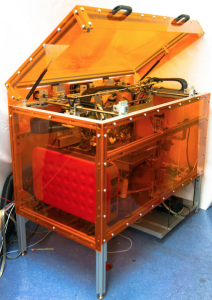

MultiFab was pieced together with $7,000 worth of off-the-shelf parts, yet MIT says that it’s more capable than 3D printers that cost several times as much. Expanding the materials available during the fabrication process essentially opens up the 3D design space. While 3D printing with two or three materials has already been done, researchers at MIT have been able to push that boundary even further, enabling a whole new range of applications for the 3D printer. The self-calibrating, self-correcting 3D printer’s ability to print up to 10 materials at one time means that it’s able to print finalized objects.

MultiFab allows users to print objects with a variety of functional properties, such as optical, electrical, mechanical, appearance, etc. It uses machine vision to scan objects in three dimensions during the printing process, checking for errors and applying correction masks when necessary. Its print resolution is an ultrafine 40 microns, less than half the size of a hair. It differs from other multi material printers through blending polymers into microscopic droplets instead of extruding melted materials that have to harden. Along with allowing MultiFab to work with more materials, this approach helps make its designs easier to scale.

An “ultimate dream” proposed by the researchers would be a system that allows local merchants who can’t afford a $7,000 printer to drop off designs at a FedEx outlet and then have finished products printed out in batches, although there’s a lot of work to be done before we can reach that point. Although Rob Enderle, the principal analyst at the Enderle Group, has said that this latest development pushes 3D printing more in line with real manufacturing hardware. He’s said that up until now, 3D printers have been little more than just a bad joke, although if you can move into really using them for short-run manufacturing, then you’re one step closer to having something in your home that could actually build what you order online the same day.

The CSAIL team has still worked to overcome two of additive manufacturing’s main challenges, which researchers identify as materials and design tools. Design tools are a critical challenge, since researchers still need to create workflows that better suit the needs of designers who work with 3D printing. Price also represents a challenge for the industry, as the really useful stuff remains expensive; for example, 3D printing a gun would cost roughly 20 times what the same gun would have cost in the store. And 3D printing remains best suited for basic objects.